Choosing the Best Commercial Pizza Oven

Commercial pizza ovens are specialised ovens that are designed specifically for the purpose of cooking pizzas. The adapted design differs to a traditional oven size and shape and perfectly suits the classic pizza format whether that's thin and crispy or full and deep crusted. They are a must-have in restaurants, pizzerias and takeaways to quickly and efficiently cook pizzas to perfection.

Here we discuss areas to consider when buying a commercial pizza oven to make sure that you make the best decision for your business.

What types of Professional Pizza Ovens are there?

There are several different types of commercial pizza ovens, including wood-fired ovens, gas-fired ovens and electric convection ovens with single and double deck options and conveyor pizza ovens.

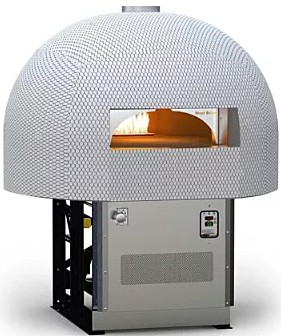

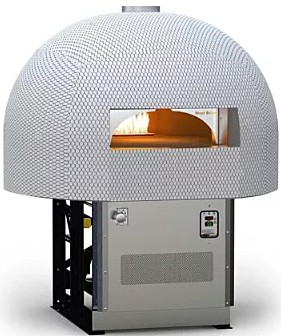

Deck Pizza Ovens

Deck ovens are the most common form of commercial pizza oven. Most use either a stone, brick or ceramic tile base. Heat comes from a source below the deck, but the base allows for an even distribution of heat, therefore avoiding the normal cold spot in the centre of traditional convection ovens. Instead, both the crust and toppings cook at the same time—which gives Italian pizzas that distinctive crispiness.

Features:

- Cooks an authentic and traditional Italian pizza.

- Electric or gas.

- Comes in a range of scalable sizes from countertop ovens to freestanding ovens with multiple decks.

- Tend to have a lower production output compared to other ovens. But are often stackable meaning output can be increased to meet demand without taking up additional floor space.

- Takes around 3-6 minutes to cook.

- Requires training to use—it’s a more active cooking process because the pizzas need to be monitored and rotated to prevent burning.

- Priced between £800 to £1,500.

- Low maintenance and hold their resale value.

Best For: Businesses which need low to medium production output. For example, restaurants that serve pizzas as part of an eclectic menu or mobile pizzerias.

Deck ovens can also use electric or gas. Electric versions use a heating element in the top of the oven and fans to re-create the heat distribution found in more traditional deck ovens. Gas versions most often feature burners mounted at the top and rear of the oven and produce a comparable cook.

Gas Pizza Ovens

Gas pizza ovens are fuelled by natural gas or propane and are known for their speed and authentic results. Mainly laid out as deck ovens which can be placed on a stand, on existing countertops and can often be stacked.

Electric Pizza Ovens

Electric pizza ovens use electric elements to create heat to cook the pizzas. Pizzas may need to be rotated to produce even results. Electric alternatives to gas deck pizza ovens can also be freestanding or countertop for flexibility of placement. Electric deck pizza ovens may be able to be stacked for additional oven capacity without an increased footprint. Always check the power supply, whether single phase or three phase and be sure that your building can support the necessary power requirements.

Wood fired Pizza Ovens

Wood-fired ovens are heated by wood or charcoal and are prized for their ability to impart a smoky flavour to the pizzas they cook. Wood fired pizza ovens will typically be used outside and so aren't suitable for the indoor business requirements. They produce rapid results and even heat distribution perfect for high demand pizza places that want to showcase the cooking process. Producing a slightly smoky flavour that is truely unique to the traditional pizza cooking technique, they are a firm favourite with pizza connaiseurs.

Conveyor Pizza Ovens

Larger than standard deck ovens, conveyor pizza ovens pass pizza slowly through the oven, entering uncooked one end and coming out the other end deliciously baked to perfection. Perfect for large output venues due to the large size, conveyor ovens for pizza prove to be the best value for money when in constant use during service.

Conveyor ovens use a belt to move pizzas through a heated chamber at a consistent speed. The pizzas are cooked using either radiant heat, infrared head or forced air impingement.

Radiant ovens, like conventional ovens, use heating elements above and below the belt to heat the air inside the chamber as well as the interior walls. Infrared ovens also use heating elements, but ceramic ones—which allow for much faster cooking times. However, impinger ovens are the most effective. They use a fan to force high-pressured hot air over the pizzas, which can reduce cook times by up to 25%.

Features:

- Much more consistent than conventional and deck ovens. There is no room for error and all products are produced to the same standard.

- Electric or gas.

- Doesn’t lose time on heat recovery, because there’s no door to open it maintains the same temperature throughout cooking.

- Automates the cooking process allowing for high production output. Are also stackable.

- Takes around 3-5 minutes to cook.

- Ease of operation means it can be used without training, reducing costs.

- Priced between £4,000 and £16,000.

- Need a lot of floor space and can also be expensive to maintain—there are a lot more moving parts that can break.

Best For: Large-scale restaurants with a high production output and the floor space to match.

Pizza Oven Alternatives

Commercial Convection Oven

Commercial convection ovens tend to be more economical than investing in a more serious piece of kit. It’s a versatile oven and most restaurants will already have one for other purposes.

However, it’s important to consider that despite the fact that all pizzas can be cooked in a convection oven, they tend to cook from the outside in. This can lead to pizzas with burnt crusts and uncooked centres. Therefore, look to purchase a high-end unit that circulates heat evenly throughout the oven.

Best For: Restaurants that don’t need to regularly produce large amounts of pizzas.

What should I look for when I buy a commercial pizza oven?

There are a few key things to consider when purchasing a commercial pizza oven:

- Size: Make sure the oven is large enough to accommodate the number of pizzas you need to cook at once.

- Fuel type: Decide whether you want a wood-fired, gas-fired, or convection oven and choose accordingly. Gas ovens typically produce more rustic, authentic results while electric models can often be more energy efficient and may require less training. Gas pizza ovens will require additional extraction so be sure to check UK regulations.

- Temperature range: Make sure the oven can reach the high temperatures needed to cook pizzas properly and achieve the results you're looking for.

- Ease of use: Look for an oven that is easy to operate and maintain. Not only does this make it easier during busy services, but new staff will not require extensive training to achieve great results.

- Price: Determine your budget and look for an oven that fits within it. Never scrimp where possible as not only may this affect the performance of the commercial pizza oven but will also affect the longevity of the equipment.

- Brand: Research different brands and read reviews to find an oven that has a good reputation for quality and reliability. Lincat pizza ovens offer the perfect blend of performance, quality and value for money and are popular with many pizzerias and professional kitchens.

- Warranty: Choose a warranty cover suitable for your needs. We always recommend a full parts and labour warranty where possible to cover any mechanical fault or equipment issues that may arise without additional cost.

Pizza Oven Features can make all the Difference

Additional features can make pizza production a more precise task especially when demand is high and quick turnover is paramount. Look out for extras including:

- Timers - produce alerts to notify when cooking times have been achieved so that busy staff never forget to remove freshly baked pizzas again. Timers can also help to produce repeatable pizzas with consistent results.

- Oven base - typically made of stone or ceramic, pizza oven bases are designed for direct contact with the pizza base and will absorb moisture and water to help achieve the desired crispness to the base. Also known as baking stones or fire stones, the same effect can be partially reproduced using a pizza stone in a regular oven.

- Aesthetics and design - where will your commercial pizza oven be situated. A theatre kitchen where the oven will be on display means that aesthetics will matter. Choosing something with an interesting, attractive design can create a focal point for guests. When ovens are to remain behind the scenes in the kitchen, standard stainless steel materials are sufficient.

- Glass or solid door - commercial pizza ovens, generally deck styles, are available with glass or solid doors. If chefs prefer to view the contents.

- Heat recovery - deck pizza ovens both gas and electric feature doors which lock heat into the oven chamber during cooking. This means however, that when the door is opened this heat escapes and the temperature drops in the oven. It may take time for the oven to return to its optimum temperature. Conveyor pizza ovens don't really have a recovery time as there are no doors and so the conveyor or oven area remains at a more consistent temperature.

Ask the Advice of the Experts

If you need help choosing the best commercial pizza oven for your business, get in touch with our team today to discuss your requirements and let us help you make the perfect choice. You may also want to take a look at our Top 3 Essentials for Developng a PIzza Kitchen post to make sure your kitchen is fully prepared to boss the pizza market.