You’re researching potential catering appliances and want to be sure that whatever you decide on, it is fully tailored to your requirements. The features, manufacture, capacity and dimensions are generally straight forward, but then you see the power information! Smaller items will often be easier to understand and digest while, the larger the equipment, the more confusing the specifications seem to be. This is due to the unit requiring a larger power supply. Before you complete your order make sure you understand the basics to guarantee that your premises is set up to accommodate your purchase.

Here we offer the truth surrounding single phase and 3 phase power supplies, breaking down the basics and hopefully making your decision clearer.

Understanding Single Phase and Three Phase Catering Equipment

In the world of commercial catering, understanding the difference between single-phase and three-phase electric supply is crucial for businesses, restaurants, and those involved in the culinary industry.

When selecting between single phase and three phase catering equipment, several key considerations must be evaluated, including the electrical load requirements, the type of appliances used and safety standards.

Factors such as the size of the business and budget constraints can influence decisions as well as energy efficiency which can significantly impact operational costs, particularly for restaurants or cafés relying on heavy-duty appliances that consume a considerable amount of power.

Your premises will also be a major factor. If the building is not set up for a 3ph electrical supply, it can be costly to adapt. Conversely, this may be a necessary investment if you require more powerful catering equipment. Single phase and three phase catering equipment are not interchangeable. The type of equipment needed will depend on the power supply available in your specific location. Using the wrong type of equipment can lead to safety hazards and damage to the equipment.

A thorough understanding of the equipment's compatibility with existing infrastructure can prevent costly alterations later on. Ultimately, consulting with a qualified electrician ensures adherence to necessary safety regulations and optimal performance, making it an invaluable step in achieving a well-functioning catering environment.

These electric supplies are designed to accommodate various types of commercial catering equipment, enabling them to operate efficiently and safely. A qualified electrician will often evaluate the needs of your business to determine whether single-phase or three-phase is the most suitable option.

It is essential to recognise that the choice between these two types of electricity can have significant implications for performance, safety, and overall energy consumption.

Power Definitions & Calculations

Amps (Amperes); this unit determines the constant electrical current required and the strength of the power drawn by the equipment.

Volts (Voltage); this unit reflects the amount of power drawn from the mains supply when the unit is in operation.

Watts (Wattage); this unit signifies the total electrical power (amps + volts) being used.

| Watts | = | Amps | x | Volts | e.g. 10 Amps x 120 Volts = 1200 Watts |

| Amps | = | Watts | / | Volts | e.g. 2400 Watts / 120 Volts = 20 Amps |

| Volts | = | Watts | / | Amps | e.g. 2400 Watts / 10 Amps = 240 Volts |

Single Phase; standard 3 pin plug

These single phase connections are most commonly seen in residential properties however can also be found in smaller, less powerful commercial units. Often referred to as a ‘plug and play’ option, units with this power type are supplied complete; fully fitted and ready to use.

It provides a consistent voltage level that is suitable for lower power requirements, often seen in appliances like refrigerators used in restaurants.

This power option will carry 220-240 Volts as standard and is capable of carrying up to and including 13 amps. The single electrical flow (or phase) is indicated in the name.

Single phase connections provide a steady and reliable power source essential for various catering equipment, such as toasters, commercial microwaves, and many commercial dishwashers.

Single Phase; hardwired

When equipment requires increased power above 13 amps, it will not be supplied with a standard 3 pin plug, instead needing to be wired directly into a fused spur.

Where equipment is frequently operational, having a hardwired connection mitigates the risk of accidental disconnection and electrical faults. This specialised installation provides a dedicated power source, ensuring that essential appliances such as ovens and refrigerators function optimally without interruptions.

Typically, this type of supply will carry 230-240 Volts. Appliances with a single phase hardwired supply should only be installed by a qualified electrician!

Three Phase; hardwired or commando plug

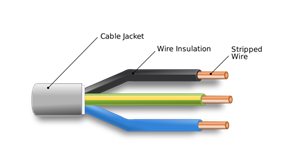

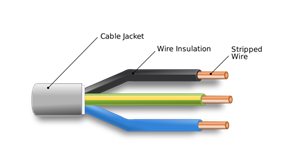

Large commercial equipment will often require a large power supply in order to work efficiently. Three phase power provides 3 separate electrical supplies (or phases) to the unit through one fixture, each phase reaching its peak sequentially meaning that power is continuously delivered with no drops in power experienced. Each individual phase will carry its own number of amps.

This type of industrial electrical supply will generally carry 415 Volts meaning that equipment with increased power can be purchased for larger businesses. Such systems also handle increased amp ratings, allowing for multiple heavy-duty appliances such as some combi ovens, certain electric oven ranges and some pass through dishwashers, to function simultaneously, a necessity in bustling kitchens.

As with single phase harwired connections, 3ph hardwired will require direct wiring. A commando plug is a 5 pin connection held within a plastic casing and is a high power alternative to standard 3 pin plugs.

If you are looking to invest in an appliance with a 3 phase supply your premises must be set up to accommodate this. Before making any purchase always seek the advice of a qualified electrician to determine if your property will support the increased power. The cost to convert your premises to a 3 phase supply can be eye-watering so make sure you get a few quotes to complete any necessary work prior to purchasing equipment, helping you to assess if this is the most appropriate and financially viable course of action. All 3 phase equipment must be installed by a qualified electrician!

Benefits of Single Phase Connections

3 Pin Plugs

- Ensures a manageable power supply.

- Reduces the risk of overloads; the inclusion of a fuse adds an essential safety feature, providing crucial protection against potential overloads.

- Facilitates easy installation and maintenance.

- Lower equipment costs

- Reduced electricity consumption

Safety considerations are paramount. Proper earthing, circuit protection, and adherence to electrical regulations are crucial to mitigate risks such as electric shocks or equipment malfunctions.

Hardwiring

- Increased safety, as the risk of overheating and fire hazards associated with loose connections is significantly reduced.

- Enhanced durability, suited for the demands of a commercial kitchen, where plugs may experience wear and tear.

- Simplified maintenance, since hardwired systems allow for easier access during troubleshooting.

Engaging a qualified electrician is crucial. They guarantee that the installation adheres to local regulations and safety standards, thus providing peace of mind and can evaluate the specific power requirements of the catering equipment, ensuring an efficient setup that meets the demands of a high-volume environment.

Benefits of Three Phase Connections

- Efficient energy consumption; in a three-phase system, the load is balanced across multiple currents, which maximises efficiency and reduces energy loss over longer distances.

- Reduced operational costs; while the initial setup cost for a three-phase system may be higher, the reduced operational costs due to increased efficiency can lead to long-term savings.

- Improved performance of equipment.

- The steady supply of power reduces wear and tear on machinery and reduces the chance of electrical overloading.

- They eliminate the need for extension leads, further decreasing the risk of accidents and electrical fires.

- Professional installation by a qualified electrician ensures compliance with local regulations and standards, safeguarding both the equipment and the establishment.

Safety considerations must not be overlooked; three-phase systems require appropriate protective measures against overloads due to their higher power outputs, leading to potential hazards if not properly managed.

Best Practice for Electrical Connections

It’s essential to adhere to safety standards such as the Wiring Regulations (BS 7671) to avoid hazards such as electrical fires.

- Use dedicated circuits: Each major appliance should ideally have its own circuit to prevent overload.

- Verify compatibility: Ensure cords and sockets of 1ph electrical connections are rated for the equipment’s voltage and current.

- Routine inspections: Regularly check electrical connections to identify wear or degradation.

- Correct installation: Businesses must ensure that installations are completed by qualified electricians.