Are you finding it tricky to keep your commercial kitchen up-to-date with FOG rules? Well, you're in good company! This post will tell you what equipment could lead to FOG and give you recommended grease management solutions as well as discuss how certain catering equipment can tackle FOG and new features that manufacturers are incorporating to beat the risk of fatbergs. It is critical that restaurant owners, professional chefs, and catering business managers all stay compliant, observing regulations and avoiding potential fines or prosecution.

What is FOG?

FOG, which stands for Fats, Oils, and Grease, is a byproduct of commercial kitchen operations and food services. It is created from cooking that uses or produces fats, oils, and greasy substances as waste. When FOG cools and is not disposed of properly, it becomes solid and will clog drains, pipes, and sewers.

A number of kitchen equipment and appliances produce fats, oils, and grease waste. Some examples include grill ranges, deep fryers, combi ovens, and rotisserie ovens. FOG can block drains, causing structural damage to pipework and causing environmental repercussions.

FOG, produced during cooking and food production, can also be released into main sewer systems through equipment channels that aren't as obvious as you think. Other FOG sources include dishwashers, sinks, food processors, and floor drains.

Commercial Equipment and Facilities That May Produce FOG

- Commercial Fryers:

- Used for frying food items, commercial fryers immerse food in hot oil, causing fats and oils from the food to mix with the frying oil.

- FOG Production Level: High.

- Griddles and Grills:

- Used to cook various food items directly on their surfaces, griddles and grills extract fats and oils from the food during the cooking process.

- FOG Production Level: Medium to High, depending on the type and quantity of food being cooked.

- Combi Ovens:

- Capable of multiple cooking methods, combi ovens can produce FOG when used for roasting or baking fatty foods.

- FOG Production Level: High, but can vary based on usage.

- Rotisseries:

- Used for cooking large cuts of meat, rotisseries rotate the meat allowing fats to drip and accumulate.

- FOG Production Level: High, particularly when cooking fatty meats.

- Braising/ Boiling/ Bratt Pans and Tilting Skillets:

- Used to fry, sauté, braise, and simmer food, these pans and skillets heat food and cause the fats and oils within to liquefy and accumulate.

- FOG Production Level: Medium - High.

- Wok Ranges and Stir Fry Stations:

- Used for stir-frying, these stations heat large quantities of oil and food, causing fats to melt and mix with the oil.

- FOG Production Level: High.

- Pasta Cookers/Potato Peelers:

- Used for boiling pasta/peeling large quantities of potatoes which release starch. While not exactly FOG, it can potentially cause issues within the drainage system.

- FOG Production Level: FOG production is 0; however, starch could potentially be a problem.

- Dishwashers and Pot/Utensil Washers:

- While not a direct source of FOG, dishwashers can contribute to FOG accumulation in drains and grease traps due to washing dishes and cookware that have fats, oils, and grease on them.

- FOG Production Level: FOG production is 0; however, the output of FOG into wastewater systems is Medium - High.

- Pot Wash Sinks:

- Used to rinse and wash used dinnerware, cutlery and cookware before entering dishwashers/pot and utensil washers for in-depth cleaning.

- FOG Production Level: FOG production is 0; however, FOG output into wastewater systems is High.

- Food Prep Sinks:

- Used to rinse/wash ingredients before preparation.

- FOG Production Level: FOG production is 0; FOG output into wastewater systems is Low.

- Floor Drains:

- Spaced around kitchen floors to ensure any spillages or floor cleaning can be easily dealt with without any safety hazards.

- FOG Production Level: FOG production is 0; FOG output into wastewater systems depends on the size of the kitchen and level of operations.

By understanding the potential FOG production levels or contributing levels of these pieces of commercial kitchen equipment, operators can implement appropriate measures to manage and mitigate the risks associated with FOG accumulation, ensuring a safer and more efficient kitchen operation.

Recommended Grease Management Solutions for Kitchen Equipment Type

Stringent grease management practices are critical in any commercial kitchen, especially when it comes to equipment. However, even rigorous practices and procedures are insufficient alone, so it's vital to have alternative and effective solutions where possible to avoid FOG (Fats, Oils, and Grease) accumulation. Read more about Why Great Grease Management Practices Don't Eliminate the Need for a Grease Trap.

FOG producing equipment such as commercial griddles and commercial deep fryers need regular cleaning and maintenance. This equipment is not connected to a mains outlet and so wouldn't require a dedicated grease trap. However, strict grease management practices and correct disposal of grease are imperative, as is a suitable grease management solution for sinks where equipment is rinsed.

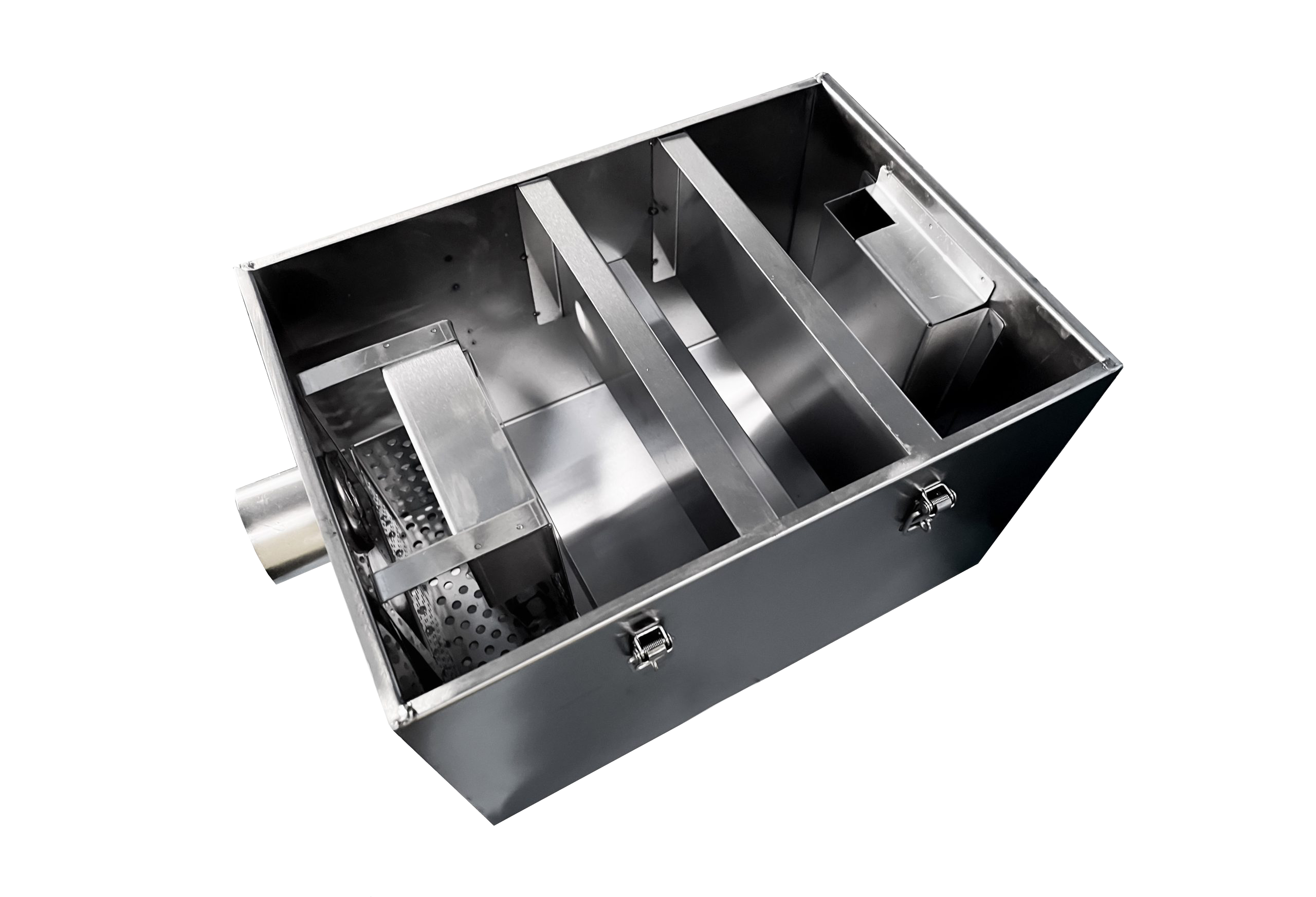

It is recommended that combi ovens, wok ranges, self-cleaning rotisserie ovens, and bratt pans with a mains water connection have correctly sized passive manual grease traps, automatic grease traps, or GRUs.

In the case of pasta cookers and potato peelers that produce starch and that have a connection to the main water supply, bio-dosing systems should be sufficient. However, always check with your local water authority for verification.

When it comes to commercial dish washers, pot and utensil washers and any commercial sinks, a grease trap should always be correctly installed. A manual passive grease trap or automatic grease trap that is correctly sized for the total flow rate is recommended.

These scenarios give examples of the type of grease management solution on a unit by unit basis. However, it isn't a workable or viable solution for the majority of businesses to have individual solutions per equipment. There are a couple of solutions to address this issue.

Firstly, you could calculate the total flow rate of water through equipment for the entire kitchen and then install one , two or more grease traps depending on the size and flow rate of the kitchen, either passive manual stainless steel grease traps or automatic grease traps (GRU's), at strategic points around the kitchen, at the last point before waste water enters the main sewer system. Where equipment has a very high output of FOG, water authorities may require a dedicated grease trap specifically for that unit. Find out more about How Do I Know If I Should Get a Manual or Automatic Grease Trap?

Secondly, you could opt for a large external or underground grease interceptor, or outdoor epoxy grease traps, through which all the drainage and kitchen waste water is connected and flows through. What is the Best Material for a Grease Trap?

Bio-dosing systems such as GreasePak, can be used in conjunction with other grease management solutions or as stated above, in relation to equipment that produces potentially harmful substances such as starch. Bio-dosers release measured quantities of solutions containing bacteria into grease traps or directly into pipes or drains to break down FOG. These solutions can reduce the frequency of cleaning required for grease traps.

Regardless of the grease trap option that is best for your business, staff education plays a huge role in ensuring the effectiveness of grease management solutions for all equipment types. Training employees on proper maintenance and emphasising the importance of grease management will result in better overall kitchen hygiene and help to prevent blockages and, potentially, costly fines.

How Commercial Catering Equipment is Fighting the FOG

There’s a serious problem with FOGs. Often, the fats, oils, and grease we use as we cook end up slipping down our drains and into the sewers, where they cool and solidify. Over time, FOGs accumulate in those sewers and form fatbergs, which block the tunnels and cost water companies thousands of pounds and man-hours to remove. While the impact of fatbergs on the environment is bad enough, recently, we’ve seen the costs being passed onto food businesses in the form of hefty fines.

Luckily, there are a few ways food businesses can avoid contributing to the FOG problem in the first place and so dodge those pesky financial penalties, from installing ever-needed grease traps to investing in quality cookware:

- The Synergy Grill: These grills atomise grease and fat while you cook, creating easy-to-clean dry debris.

- Valentine Commercial Fryers with Oil Filtration: Filtering debris from oil allows for reuse and reduces oil waste. Vito Oil Filtration systems can also be used on any compatible commercial fryer.

- Rational: Rational combi ovens offer an innovative Grease Drip Collector option which sits below the unit and collect grease. The grease can be left to cool and then disposed of via the collector tap. Rational can also offers a centrifugal grease extraction system which can be incorporated into equipment to ensure clean cooking air and no need for grease filters.

- Unox:The SMART drain is a two-way programmable valve that works in sync with cooking programs and sits below the oven and above a container which, when full, can be swapped out.

You may even want to avoid oil altogether by using:

- Non-Stick Cookware: Reduces the need for grease in cooking.

- Sous Vide: Eliminates the need for oil-based cooking with a water bath method of cooking.

By combining effective grease management in the kitchen, employing suitable grease traps and investing in some choice pieces of catering equipment, you can be sure that your business is doing its bit to fight FOG.